In the relentless battle against corrosion, coatings emerge as a stalwart defense mechanism. These versatile sheaths of material act as a physical barrier between susceptible substrates and the corrosive elements of our environment. By establishing a robust boundary, coatings effectively suppress the electrochemical reactions that lead in rust, degradation, and structural damage. From industrial equipment to automotive finishes, coatings deliver vital protection against the ravages of time and environmental exposure.

- Diverse types of coatings are available, each tailored to meet specific application requirements.

- Synthetic coatings often serve as a first line of defense against mild corrosion.

- Ceramic coatings offer enhanced durability and resistance to harsh conditions.

Corrosion Prevention Strategies for Durable Materials

preventing corrosion is crucial for ensuring the longevity and performance of materials used in a spectrum of industries. Employing effective techniques can significantly extend the lifespan of equipment, installations, and commodities. A comprehensive strategy to corrosion control typically involves a combination of factors.

Initially, selecting materials with inherent resistance to rusting is paramount. , creating protective barriers, such as coatings or membranes, can act as a physical barrier against corrosive agents. Furthermore, controlling the environment through measures like humidity regulation and oxygen minimization can significantly alleviate the risk of corrosion.

Regular inspections are essential for identifying early signs of deterioration and enabling timely maintenance. By implementing a integrated approach to corrosion prevention, engineers and designers can contribute to the creation of durable and reliable materials that withstand the test of time.

Grasping the Science of Coating Adhesion

Coating adhesion, a essential aspect of surface treatment, involves the joining of a coating material to a substrate. This occurrence is influenced by a complex interplay of factors, including surface characteristics, environmental conditions, and the inherent nature of both the coating and substrate materials. Successful adhesion relies on establishing strong connections at the interface between these components. Scientific understanding of these mechanisms is critical for developing durable and reliable lubricity of diesel coatings that can withstand various extraneous factors.

- Variables Affecting Adhesion:

* Surface texture: A rougher surface generally enhances adhesion due to increased contact area.

* Surface makeup: The chemical nature of the substrate and coating influences their compatibility and bonding potential.

* Environmental conditions: Temperature, humidity, and exposure to substances can significantly impact adhesion strength.

Environmental Factors and Corrosion Influence

Corrosion, the gradual deterioration of materials due to chemical reactions with their environment, is a major concern in various industries. Environmental factors play a crucial role in accelerating the corrosion process. Moisture, often present in humid climates or near water bodies, promote corrosion by providing an electrolyte for electrochemical reactions.

- Heat

- Airborne contaminants

- Saltwater environments

, In addition,, the presence of acid rain can significantly worsen corrosion. The intensity of environmental factors indirectly influences the rate and extent of corrosion, making it essential to consider these factors in the design and maintenance of structures and equipment.

Advanced Coatings for Extreme Environments

Pioneering coatings that withstand harsh environmental situations is a field of dedicated research. These state-of-the-art materials are critical for a variety of applications, from military operations to geothermal exploration. Recent advancements in material science have led to the creation of coatings with unparalleled properties such as thermal resistance, wear protection, and regenerative capabilities. Furthermore, these coatings can be optimized to meet the unique demands of each application.

- Utilizing advanced nanomaterials and hybrid structures allows for improved performance in adverse environments.

- Ongoing research efforts are focused on developing unbreakable coatings that can tolerate the most inhospitable conditions on Earth.

Effective Corrosion Inhibition Techniques

Corrosion presents a persistent problem to various industries, leading to substantial economic losses and safety concerns. Implementing effective corrosion inhibition techniques is therefore crucial for mitigating these impacts. These methods aim to reduce the rate of corrosion by creating a protective barrier on the metal surface or by modifying the corrosive environment. Common approaches include the use of films, which act as physical barriers against corrosive agents. Moreover, chemical inhibitors can be introduced into the corrosive environment to slow down the corrosion process by forming a passive layer on the metal surface.

Numerous factors, such as temperature, pH, and the presence ofsalts, influence the effectiveness of corrosion inhibition techniques. Therefore, selecting the most appropriate method relies on the specific application and environmental conditions. By implementing a comprehensive corrosion management strategy that includes routine monitoring and timely repairs, industries can effectively combat corrosion and maintain the longevity of their assets.

Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now! Pauley Perrette Then & Now!

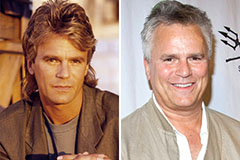

Pauley Perrette Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!